The Pulp and Paper Industry is moving onto a new era, one that is defined not just by material production, but by intelligent automation and data-driven decision-making. For the industry, the integration of Artificial Intelligence (AI) is proving to be a critical lever in achieving operational excellence, reducing environmental impact, and responding faster to shifting market dynamics. As traditional manufacturing processes face growing pressure to be more agile and efficient, forward-thinking companies are turning to AI to gain competitive advantage. It has become essential to understand how AI is capable of transforming key aspects of pulp and paper operations and why key decision-makers from the industry could prioritize strategic investment in these technologies.

1. Enhancing Operational Efficiency

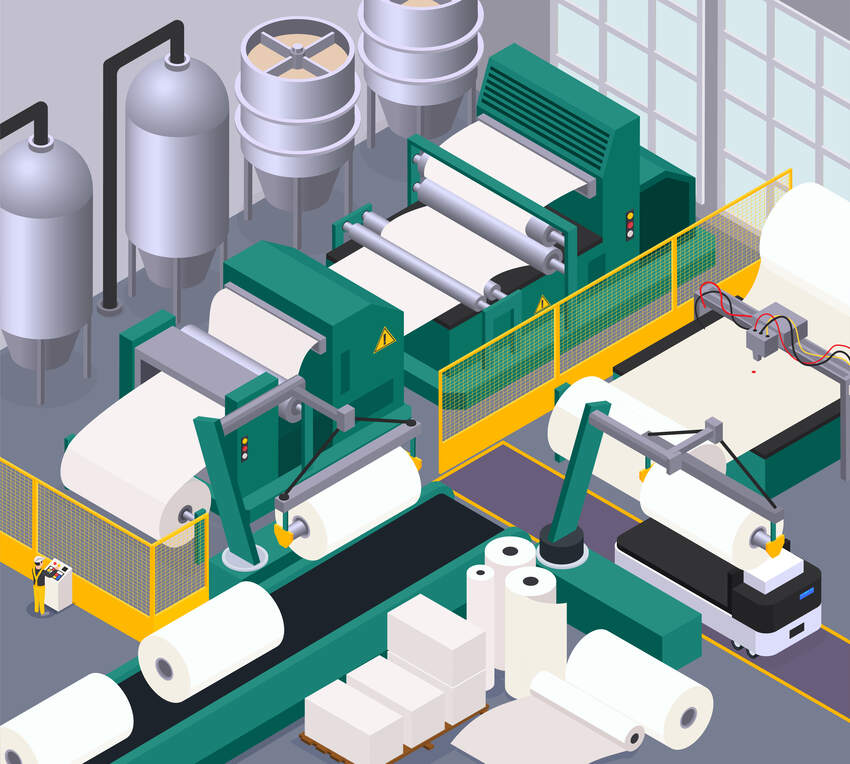

AI-powered systems are driving real-time optimization across pulp and paper manufacturing processes. From controlling pulp consistency to regulating drying temperatures, AI algorithms can analyze sensor data and automatically adjust machine parameters. This level of precision ensures continuous, high-quality production and significantly reduces waste. For plant managers and operations executives, this translates to better yield, lower energy costs, and minimized downtime.

2. Predictive Maintenance for Capital Asset Protection

Unexpected equipment failures can result in costly delays and safety risks. AI enables predictive maintenance by identifying subtle performance deviations that may signal component wear or impending failure. Leveraging machine learning models trained on historical equipment data, mills can proactively schedule repairs or replacements, avoiding unplanned shutdowns. This predictive capability not only extends the lifespan of expensive machinery but also improves uptime reliability—a key metric in any B2B service-level agreement (SLA).

3. Quality Control and Assurance

Maintaining consistent product quality is essential in B2B contracts, especially when serving packaging, printing, and hygiene markets. AI-driven vision systems can detect defects like fiber inconsistencies, thickness variations, or surface anomalies at high speeds. These systems provide granular quality analytics and enable real-time corrections, ensuring conformity with client specifications. In regulated industries, AI also supports digital traceability for compliance and reporting.

4. Intelligent Supply Chain and Demand Forecasting

AI enhances end-to-end supply chain visibility by integrating data from procurement, inventory, production, and logistics. With predictive analytics, companies can anticipate market demand shifts, optimize inventory levels, and reduce lead times. For example, machine learning models can forecast raw material needs or transportation bottlenecks, empowering procurement and logistics teams to respond dynamically. B2B customers benefit from more reliable delivery schedules and fewer order fulfillment errors.

5. Sustainability Through Smart Resource Management

With rising ESG (Environmental, Social, and Governance) expectations, paper companies are under pressure to reduce their ecological footprint. AI helps mills track and manage energy, water, and chemical usage more efficiently. By analyzing process performance in real time, AI tools suggest ways to lower emissions or improve material reuse. These insights not only support sustainability goals but also enhance brand reputation among eco-conscious B2B clients.

6. Product Innovation and Customization

AI empowers R&D teams to accelerate product development cycles by simulating material behavior, analyzing customer feedback, and testing formulations virtually. This capability is especially useful for B2B markets requiring tailored solutions—such as biodegradable packaging or high-strength paper products. Through AI-driven insights, manufacturers can co-develop offerings with clients, creating value-added partnerships that go beyond transactional relationships.

7. Workforce Upskilling and Organizational Agility

As AI adoption grows, so does the need for a digitally literate workforce. B2B enterprises are investing in training programs to upskill engineers, operators, and data analysts. AI not only automates routine tasks but also augments decision-making, enabling employees to focus on strategic initiatives. Organizational agility—the ability to quickly adapt to market changes—becomes a competitive advantage when teams can leverage real-time insights across functions.

Conclusion:

While Artificial Intelligence can no longer be seen as a speculative technology in the pulp and paper industry, it is rather a strategic imperative. From operational efficiency to sustainability, quality control to innovation, AI is delivering measurable business value across the supply chain. For businesses, investing in AI is about more than automation. It’s about building future-ready organizations capable of thriving in a competitive, resource-conscious global market. Companies that embrace AI today will be the ones defining tomorrow’s paper industry.